The Department of Food Processing participates in the implementation of the subprogram “Development of technologies and technical means for processing and storage of agricultural products” No. 0107U008964

Scientific directions of the Department of “Equipment for Processing and Food Production”:

-

Development of scientific foundations of energy-saving technologies for freezing and low-temperature storage of fruit and vegetable raw materials.

-

Improving the efficiency of the process of pulse, rotary-pulsation and jet homogenization of milk.

-

Improving methods of gravitational separation and grinding grain.

-

Optimization of the process of jet mixing of soft drinks.

-

Improvement of the process of recycling juice production waste.

-

Structural and parametric analysis of the characteristics of the heat exchanger that implements the milk pasteurization operation.

-

Improvement of the process of bottling food liquids.

-

Study of the physical and mechanical properties of fruit and vegetable raw materials.

-

Increase in the technological efficiency of modern dough mixers machines.

-

Justification of the parameters of the working parts of the machine for processing secondary raw materials.

STREAM-SLOT HOMOGENIZER OF MILK

The development of the homogenizer is based on the theory of hydrodynamic dispersion of milk emulsion, based on the correlation between the maximum difference in phase speeds and the Weber criterion.

PULSATION HOMOGENIZER WITH ROTOR, WHAT VIBRATES

The developed industrial sample of the homogenizer allows to obtain a milk emulsion with an average diameter of fat globules of 0.8 microns and has 4.9–6.7 times lower specific energy consumption than industrially developed milk homogenizers (including valve).

PULSATION MILK HOMOGENIZER

The economic effect of implementing the developed innovative homogenizer is 265740–362945 UAH, which is achieved by reducing specific energy consumption by 45–76% and operating costs by 35–64%.

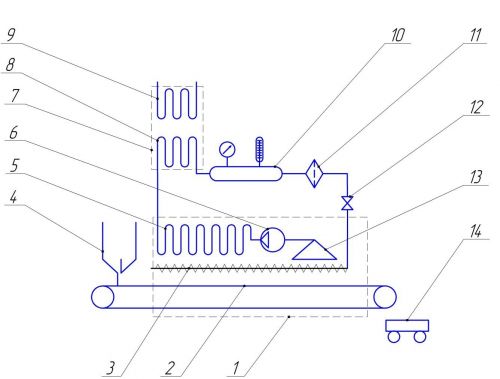

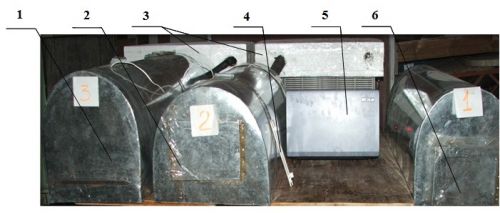

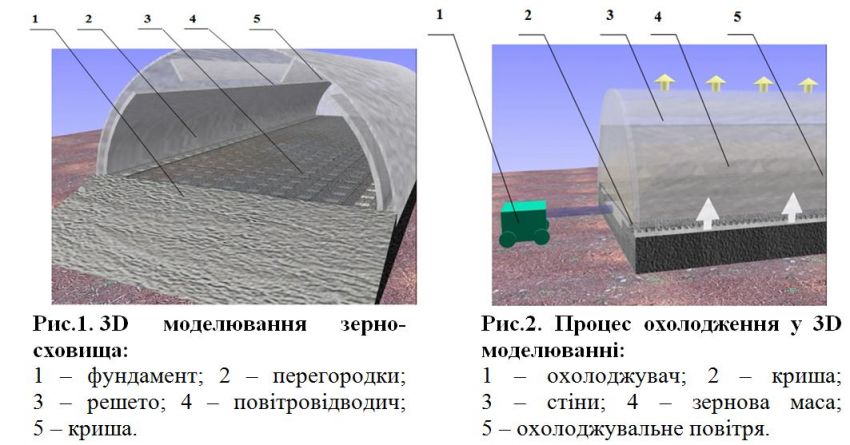

GRAIN STORES USING COOLING

This design allows you to avoid significant grain losses, preserve grain quality, and reduce storage costs. The air flow passing through the grain mass has a versatile technological effect on the grain.

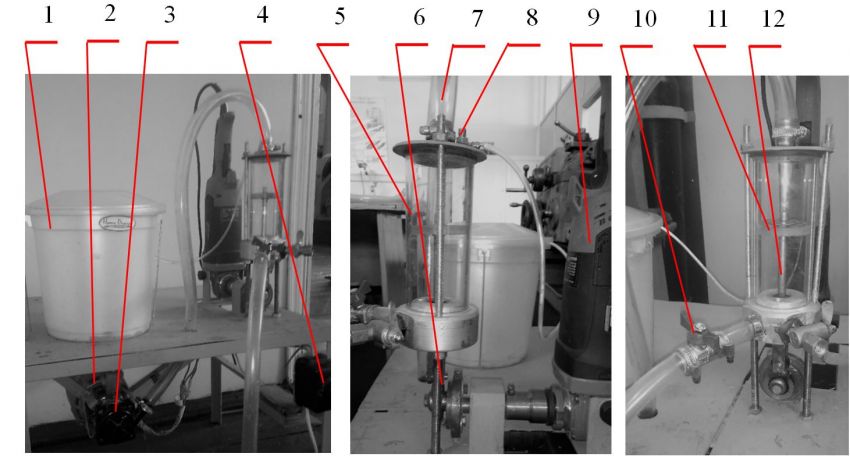

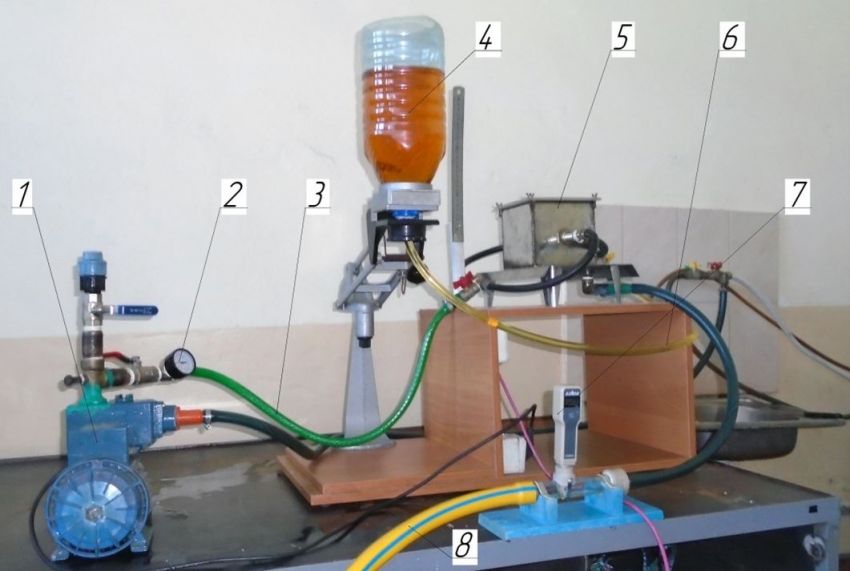

JET HOMOGENIZER WITH SEPARATE FEED OF THE FAT PHASE OF MILK

The payback period of a new homogenizer does not exceed 4–9 months.

FINGER CRUSHER GRAIN MATERIAL

The developed crusher is designed to solve the problem of intensification of the grain grinding process by crushing machines with a vertical axis of rotation of the rotor with finger working bodies intended for use in farms, feed mills and cereal factories.

COUNTER-FLOW-JET MIXER OF LIQUID FOOD PRODUCTS

The conducted theoretical and experimental studies allowed us to develop an analytical model of countercurrent-jet mixing, which links the main design and technological parameters with its energy and quality indicators.

DEVICE FOR IMPULSE FREEZING FOOD PRODUCTS

The design of the device for impulse freezing of food products allows you to reduce energy losses due to thermal insulation of the freezing chamber and vacuum receiver, increase the intensity of the freezing process by installing a vacuum receiver, which closes the freezing cycle

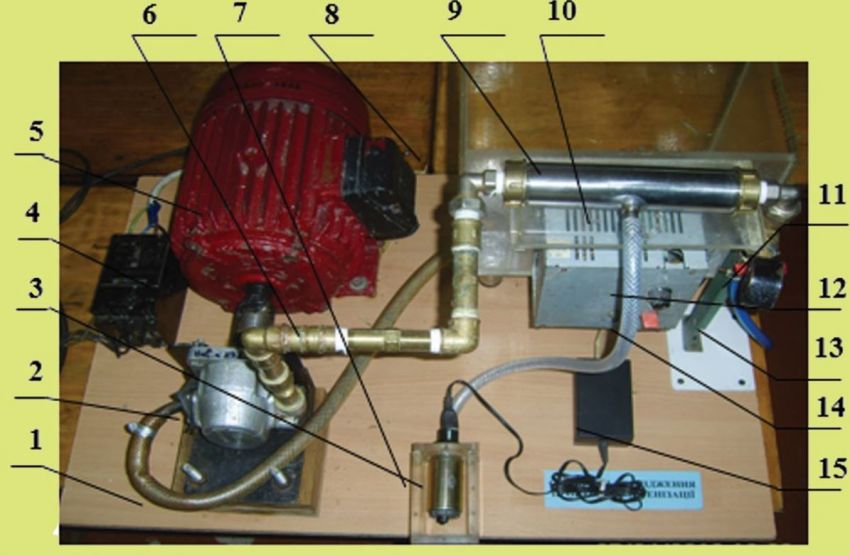

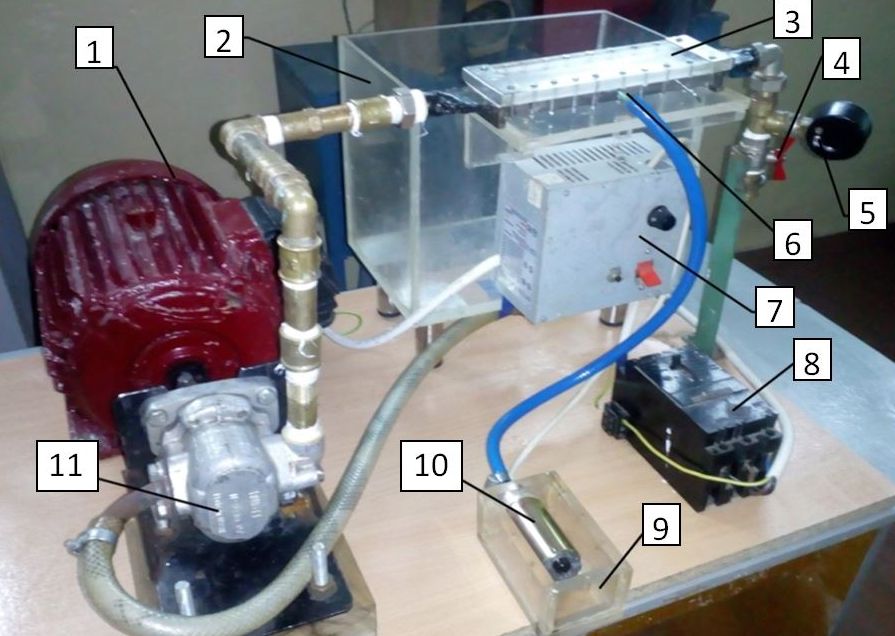

PULSE MILK HOMOGENIZER

The device belongs to the apparatus for dispersing the fat phase of milk and homogenization and can be used to obtain products with a fat emulsion dispersion of less than 1 μm (milk, milk substitutes, etc.).