Installation for calibration of seed material of fruit stone crops

Using the tilt angle control, set the desired slope of the screen part. Using the amplitude adjustment mechanism, we set the specified eccentricity. Before starting the unit, by pressing the “start” button on the control panel of the HITACHI X200 frequency converter, the set frequency of vibrations of the screen part for a particular culture is set. When the set oscillation frequency is set, the seed from the hopper is transferred to the upper sieve using the distribution board. Moreover, for cherries and sweet cherries, the thickness of the seed layer on the sieve is equal to two values of seed thickness, and for cherry plums, apricots and almonds – one thickness, to ensure the orientation of the seeds in the holes.

Authors of the development: Doctor of Technical Sciences, Associate Professor O. H. Karaiev, Candidate of Technical Sciences, Associate Professor L. Yu.Bondarenko.

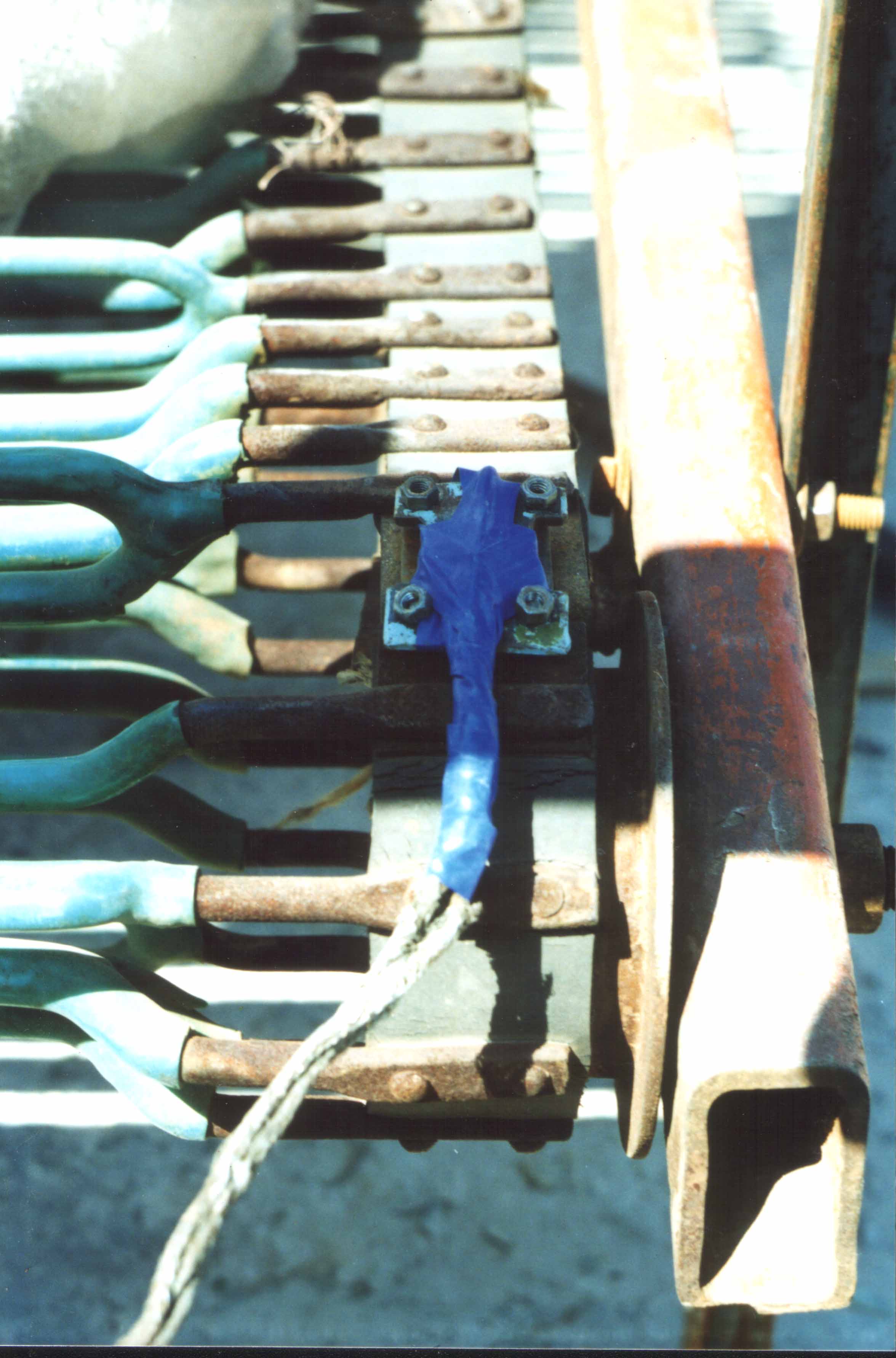

The laboratory setup is based on the TAKI-15 tomato harvester.

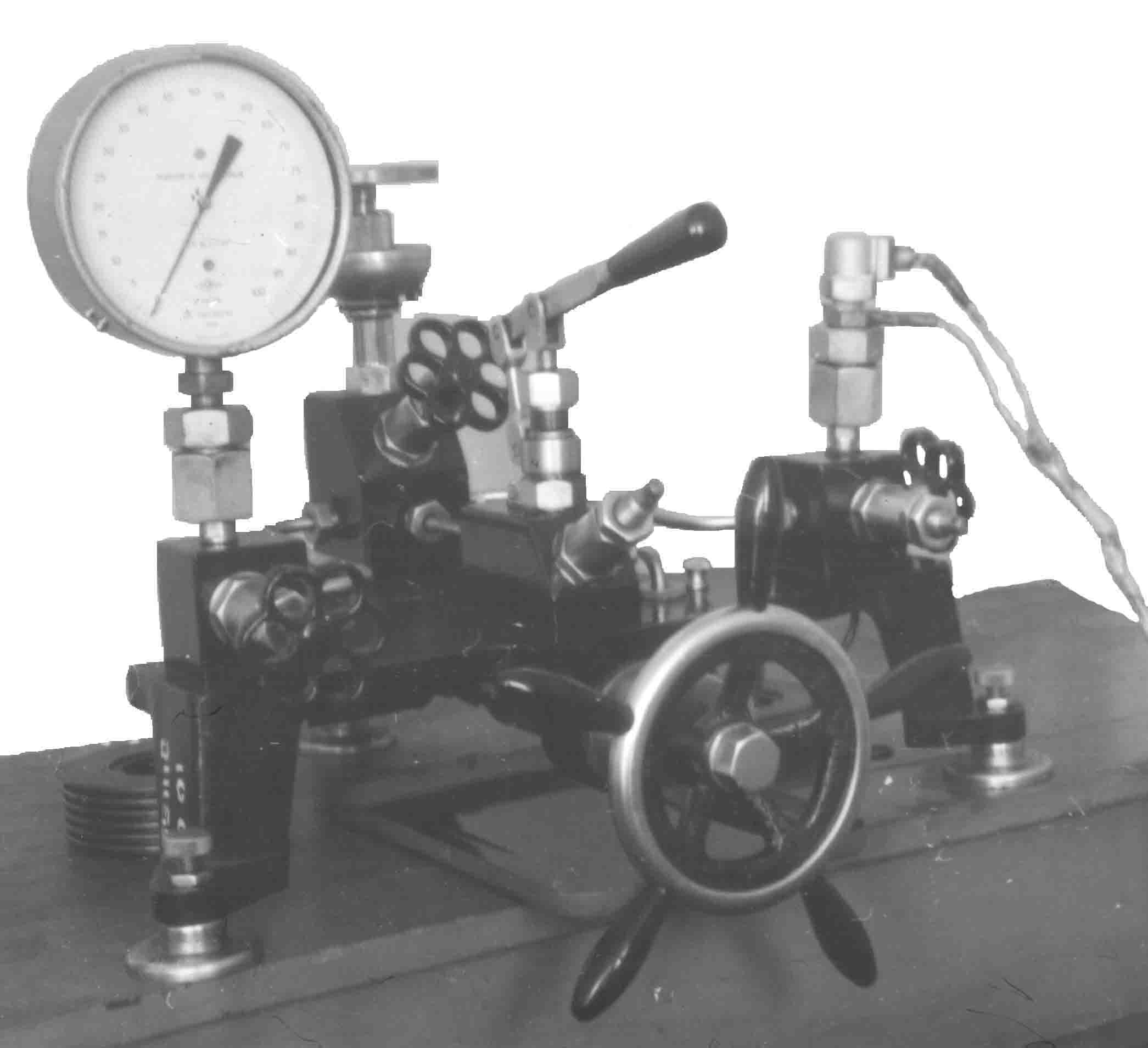

A test bench for testing a rod elevator in laboratory conditions has been developed, with the help of which the optimal parameters and operating modes of the elevator have been experimentally determined.

The main objective of the research is to determine the experimental model of the process and justify the parameters for the coefficients of dynamism in terms of force (KF) and pressure ( KP) of the system and the maximum force in the elevator belt. The use of a drive with a damping device leads to a decrease in the dynamic coefficient Kf by 8-9 %, the dynamic coefficient of pressure – by 4-5 %; the starting torque – by 11.5 % at a shaft speed of n = 150 rev/min (w = 16 r/s).

A methodology for calculating the drive of a rod elevator has been developed. This methodology contains an algorithm for determining the dynamic loads in the rod conveyor belt. This methodology and recommendations for improving the design of the elevator drive are used in the design of stationary conveyors.

Authors of the development: Doctor of Technical Sciences, Professor V.V. Tarasenko, Candidate of Technical Sciences, Associate Professor O.O. Dereza.

Wind turbine generator with a verical axis

To supply remote areas or areas with no connection to centralized electricity and heat supply systems, impossibility or excessively high cost of connection to such networks; high cost of fuel importation for generating electricity and heat on site; favorable conditions for the use of primary renewable energy sources, primarily solar or wind.

To supply remote areas or areas with no connection to centralized electricity and heat supply systems, impossibility or excessively high cost of connection to such networks; high cost of fuel importation for generating electricity and heat on site; favorable conditions for the use of primary renewable energy sources, primarily solar or wind.

A wind turbine generator with a vertical axis has two blades that are placed on a shaft at an angle of 90° to each other. The shaft is mounted in bearings on a vertical support. Under the influence of the wind force, one of the blades is always in a vertical position and moves relative to the vertical support half a turn of this support. At the same time, the other blade is in a horizontal position for half a turn relative to the vertical support. Thus, one blade generates torque, and the second blade – at this time in a horizontal position – moves along the line of wind force. When the first blade completes a half-turn, the wind moves it to a horizontal position and the second blade to a vertical position. This process continues for the next half-turn. The torque developed by the shovel in working condition is transmitted by an electric generator.The peculiarity of this design is that the blade position changes automatically under the influence of wind force, as well as the presence of one moving link – the shaft in the sleeve (utility model patent No. 50427).

Author of the development: Senior Lecturer O.Yu.Mykhailenko.

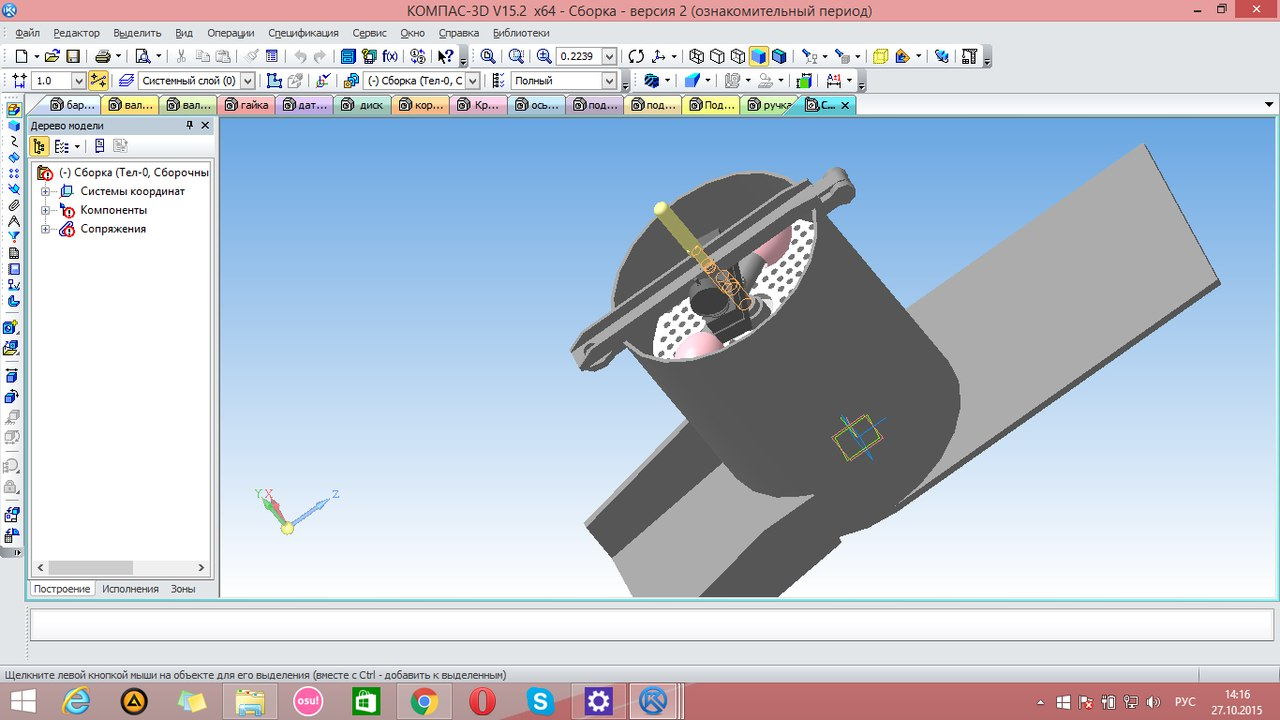

Information system for geometric modeling of cutting tools parameters for turning parts

The information system “Geometric Modeling of Cutting Tool Parameters for Turning Parts” makes it possible to automate the process of designing cutting tools and calculating cutting modes. The information system is designed in such a way that it allows the designer to significantly reduce the design process and determine the cost of the future product in advance. The developed information system is used in the educational process of Dmytro Motornyi Tavria State Agrotechnological University at the Department of Technical Mechanics and Computer Design named after V.Naidysh when teaching the course “Engineering Computer Graphics” to students of the Faculty of Power Engineering and Computer Technologies, specialty 122 “Computer science”.

The information system “Geometric Modeling of Cutting Tool Parameters for Turning Parts” makes it possible to automate the process of designing cutting tools and calculating cutting modes. The information system is designed in such a way that it allows the designer to significantly reduce the design process and determine the cost of the future product in advance. The developed information system is used in the educational process of Dmytro Motornyi Tavria State Agrotechnological University at the Department of Technical Mechanics and Computer Design named after V.Naidysh when teaching the course “Engineering Computer Graphics” to students of the Faculty of Power Engineering and Computer Technologies, specialty 122 “Computer science”.

Author of the development: Candidate of Technical Sciences, Associate Professor O.Ye. Matsulevych.

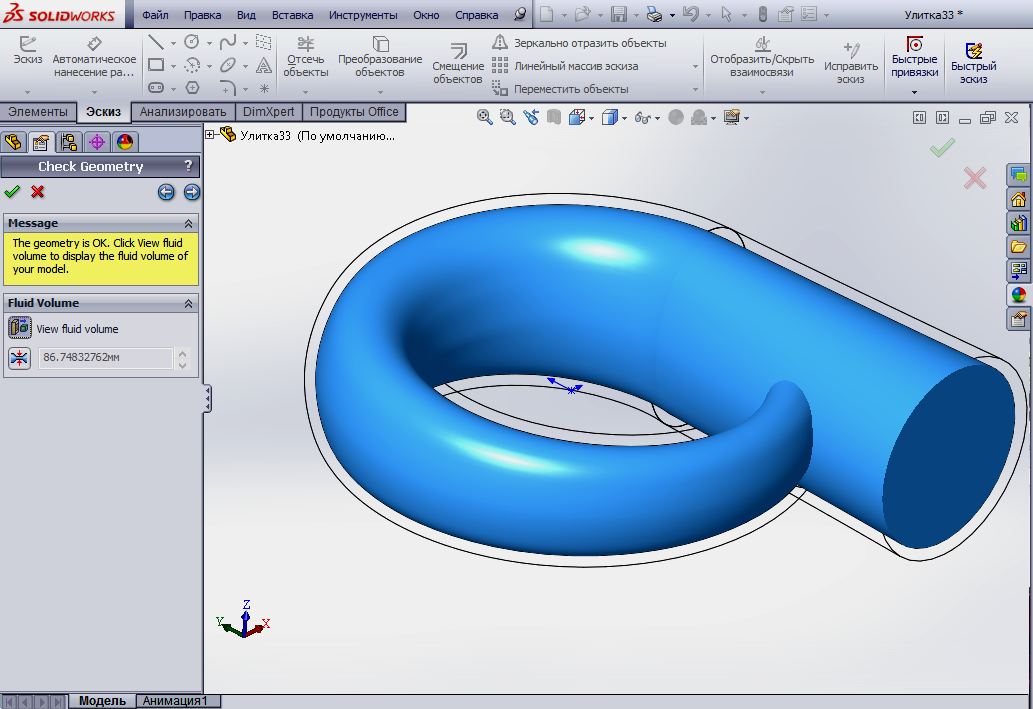

The Developed information system makes it possible to automate the process of designing functional surfaces of diesel engine turbocharger channels. This allows the designer to significantly reduce the product design process. The proposed information system for geometric modeling of functional surfaces of diesel engine turbocharger channels is used in the educational process of of Dmytro Motornyi Tavria State Agrotechnological University at the Department of Information Technologies of Design named after V.M. Naidysh when teaching the course “Engineering and Computer Graphics” to students of the Faculty of Power Engineering and Computer Technologies, Specialty 141 “Electricity, electrical engineering and electromechanics”.

The Developed information system makes it possible to automate the process of designing functional surfaces of diesel engine turbocharger channels. This allows the designer to significantly reduce the product design process. The proposed information system for geometric modeling of functional surfaces of diesel engine turbocharger channels is used in the educational process of of Dmytro Motornyi Tavria State Agrotechnological University at the Department of Information Technologies of Design named after V.M. Naidysh when teaching the course “Engineering and Computer Graphics” to students of the Faculty of Power Engineering and Computer Technologies, Specialty 141 “Electricity, electrical engineering and electromechanics”.

Author of the development: Candidate of Technical Sciences, Associate professor V.M. Shcherbyna.

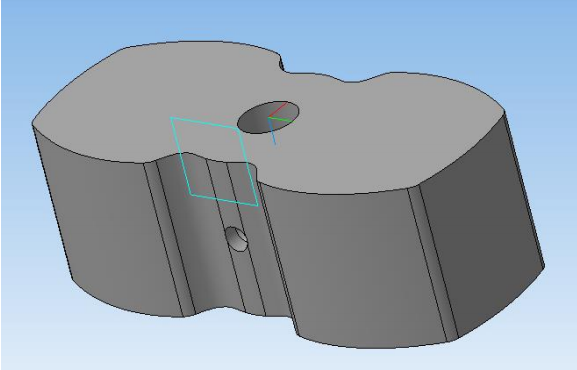

Software module of specialized APS based on ARI technologies for functional model

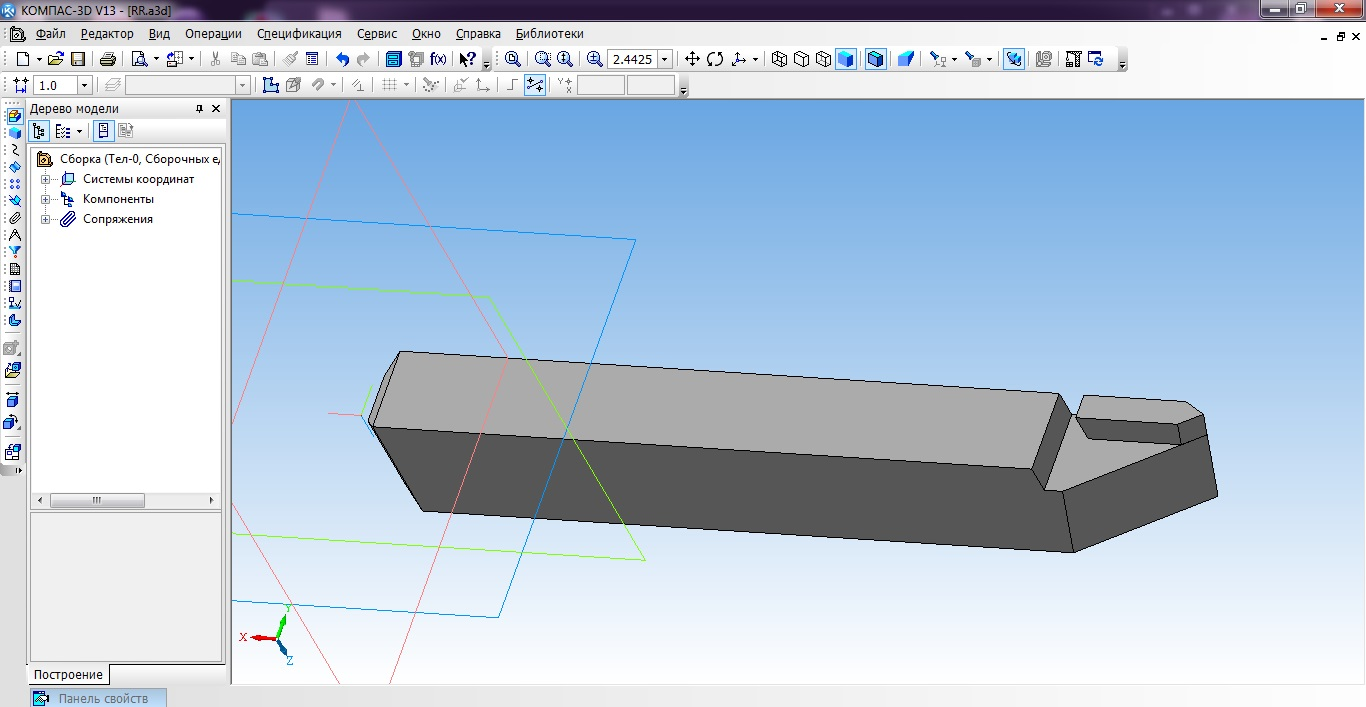

A Software module for specialized APS based on ARI technologies for a functional modelA software module for automated modeling of part parameters integrated into the KOMPAS design system has been developed, which made it possible to reduce the cost of designing a machine unit and visually observe changes in the structure of the part during its restructuring and, if necessary, adjust its geometric parameters. The proposed information system for geometric modeling of part parameters is used in the educational process of Dmytro Motornyi Tavria State Agrotechnological University at the Department of Information Technologies of Design named after V.M. Naidysh when teaching the course “Modeling of Technical Systems” to students of the Faculty of Power Engineering and Computer Technologies, specialty 133 “Industry engineering”.

A Software module for specialized APS based on ARI technologies for a functional modelA software module for automated modeling of part parameters integrated into the KOMPAS design system has been developed, which made it possible to reduce the cost of designing a machine unit and visually observe changes in the structure of the part during its restructuring and, if necessary, adjust its geometric parameters. The proposed information system for geometric modeling of part parameters is used in the educational process of Dmytro Motornyi Tavria State Agrotechnological University at the Department of Information Technologies of Design named after V.M. Naidysh when teaching the course “Modeling of Technical Systems” to students of the Faculty of Power Engineering and Computer Technologies, specialty 133 “Industry engineering”.

Author of the development: Candidate of Technical Sciences, Associate Professor I.V.Pykhtieieva.

Software for designing the working surfaces of a gas blower rotor bounded by kinematic surfaces

The developed information system makes it possible to automate the process of modeling the functional surfaces of a gas blower rotor. This allows the designer to significantly shorten the product design process. The proposed information system for geometric modeling of the working surfaces of the gas blower rotor limited by kinematic surfaces is used in the educational process of Dmytro Motornyi Tavria State Agrotechnological University at the Department of Technical Mechanics and Computer Design named after V.Naidysh when teaching the course “Fundamentals of Applied Geometry” to students of the Faculty of Power Engineering and Computer Technologies, specialty 122 “Computer science” for the Master’s degree.

The developed information system makes it possible to automate the process of modeling the functional surfaces of a gas blower rotor. This allows the designer to significantly shorten the product design process. The proposed information system for geometric modeling of the working surfaces of the gas blower rotor limited by kinematic surfaces is used in the educational process of Dmytro Motornyi Tavria State Agrotechnological University at the Department of Technical Mechanics and Computer Design named after V.Naidysh when teaching the course “Fundamentals of Applied Geometry” to students of the Faculty of Power Engineering and Computer Technologies, specialty 122 “Computer science” for the Master’s degree.

Author of the development: Candidate of Technical Sciences, Associate Professor Ye.A. Havrylenko